TNT Countertops & Cutting-Edge Technology

Boasting a collective experience of 65 years, TNT Countertops has established a lasting legacy, consistently maintaining a prestigious position in the industry. This success is attributed to our commitment to strong customer service, skilled expertise, and the strategic integration of selective technology. In this post, we delve into the technological advancements that set us apart and enhance the custom installation process. If you're intrigued by how technology can elevate the aesthetics and functionality of your countertops, read on!

Vein Matching Software:

One of the critical elements in achieving visually appealing countertops is vein matching. Veins, with their unique contrast in color, texture, and pattern, contribute significantly to the overall charm of stone surfaces. At TNT Countertops, we employ precision software designed specifically for vein matching slabs. This technology ensures a seamless flow of characteristics between two different pieces of stone, guaranteeing a visually striking and cohesive appearance in your custom installations.

Detailed Digital Imaging:

To complement the human eye, our team utilizes state-of-the-art high-powered cameras for detailed digital imaging. These cameras play a crucial role in analyzing and recording the intricate patterns, variations, and details of each slab. The information captured goes beyond what the naked eye can perceive, enabling us to make informed decisions during the design and installation process. This meticulous approach ensures that every countertop we create is a masterpiece of precision and beauty.

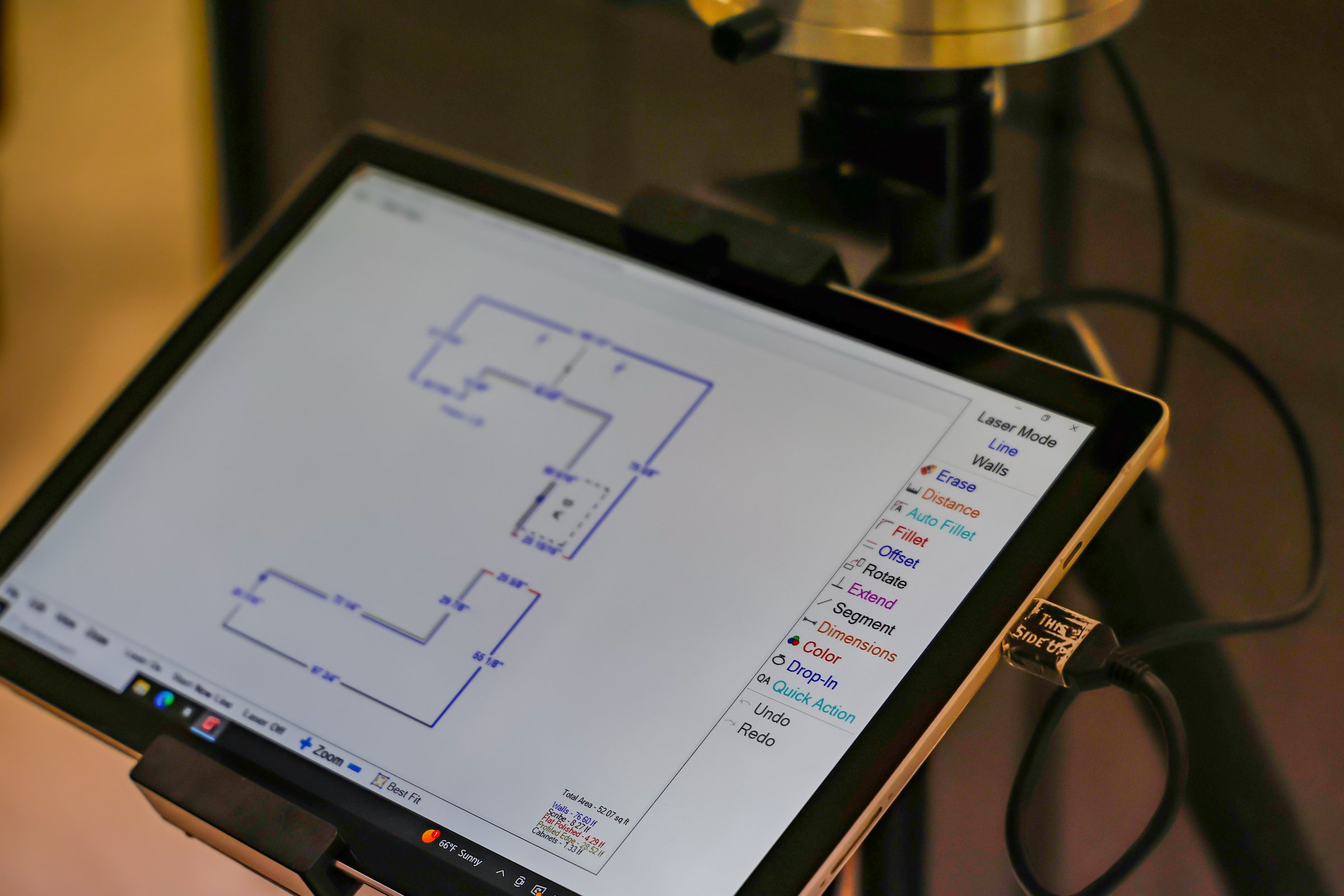

Laser Templating:

In the past, templating for countertops relied on materials like plywood or cardboard. However, TNT Countertops has embraced the future with laser templating technology. This innovation revolutionizes the accuracy of measurements and minimizes material waste. Laser templating ensures the best possible connection between your countertop and the wall, resulting in a flawless fit. Our commitment to minimizing environmental impact is reflected in this technology, as it reduces the need for excess materials, making the entire process more sustainable.

Precision Cutting with CNC Technology:

Computerized Numerical Control (CNC) technology has transformed the precision cutting process, providing uniformity and accuracy that surpass traditional methods. At TNT Countertops, we use CNC technology with computer-controlled diamond-tipped bits. These bits follow specifically provided instructions, creating countertops with unparalleled precision. The result is a product that not only meets but exceeds industry standards, offering a level of consistency that manual cutting methods cannot match.

Conclusion:

TNT Countertops remains at the forefront of the industry by combining our 65 years of experience with cutting-edge technology. Our commitment to excellence, paired with the strategic integration of advanced tools, ensures that every custom countertop installation is a testament to quality and innovation. If you're ready to turn your countertop dreams into reality, connect with us today. Experience the difference that technology, expertise, and exceptional service can make in transforming your living spaces.